The GRN provides time-stamped, verifiable proof of goods received—critical for both internal controls and external audits. The Goods Received Note (GRN) plays a pivotal role in the Procure-to-Pay (P2P) cycle, acting as a bridge between the physical receipt of goods and the financial validation required for payment. It ensures that procurement, logistics, and finance stay aligned, preventing costly errors and delays in the AP workflow.

Invoice Generation

It acts as a verification tool, ensuring that the items received at a warehouse or store correspond precisely to the items ordered from the supplier. This verification process is crucial because it directly impacts several facets of supply chain management, including inventory control, payment processing, and vendor relationships. By meticulously recording the details of received goods, businesses can avoid discrepancies that lead to stockouts, overstocking, and financial inconsistencies. A Goods Received Note (GRN) is a formal document issued by a buyer to acknowledge the receipt of goods delivered by a supplier. It is an essential part of the procurement process, ensuring that all goods listed in the purchase order are delivered in the agreed-upon quantity, quality, and condition.

Uncovering Procurement Excellence

Goods received notes can help here and make your procurement process smooth and hassle-free. They keep things organized and also help form long-term relationships with your suppliers. Procurement is a critical business process that goods received note involves the acquisition of goods and services necessary for an organization’s operations.

- Its purchase order management features automate the creation of a purchase order from an approved PR.

- When a supplier delivers the goods, the receiving team checks the package to ensure it matches the order.

- A Goods Issued Note (GIN), on the other hand, documents the issuance of goods from inventory to departments or customers, tracking the reduction in stock levels.

- A Goods Received Note (GRN) is an essential document in the supply chain management process that serves as a mutual acknowledgment between a supplier and a customer.

- It is also documentary evidence that accountants can rely on to maintain error-free account balances.

- The process of filling out a GRN can vary slightly depending on the organization’s policies and the type of inventory system in use, but generally follows a structured approach.

Why is it important to verify the received goods against the purchase order?

This reduces the chances of errors that could lead to inventory discrepancies, which are costly and time-consuming to resolve. Linking the GRN to a purchase order (PO) number allows businesses to verify that the goods received match the items that were originally ordered. Fourth, inputting incorrect data into the GRN is a surprisingly common blunder. Whether it’s a typo in the quantity or a mix-up in the unit of measure, such errors can have a ripple effect on inventory levels and financial retained earnings reporting.

What is the difference between po and GRN

This resource offers ongoing support to ensure that you can effectively utilize the software to its fullest potential. From troubleshooting to advanced tips and tricks, the help center is a valuable asset for any business looking to enhance their operations management. When selecting a GRN template for your business, consider the complexity Liability Accounts of your operations and the level of detail required in your documentation.

From the perspective of a warehouse manager, the GRN is a tool of empowerment, enabling them to maintain a real-time snapshot of inventory levels. For the financial controller, it is a cornerstone of fiscal responsibility, ensuring that the capital tied up in inventory is accurately reflected on the balance sheet. And for the procurement officer, the GRN is a checkpoint, confirming that suppliers have fulfilled their contractual obligations. The GRN is more than just a formality; it is a cornerstone of effective supply chain management. It ensures that businesses have a clear and accurate record of their inventory, which is essential for operational success and financial integrity.

The GRN plays a pivotal role in ensuring accuracy and transparency in business operations by verifying that the goods received match the details specified in the purchase order. The GRN process begins with the receipt of goods by the organization’s receiving department. Upon delivery, the items are carefully inspected to ensure they meet the specifications outlined in the purchase order. Any discrepancies, such as damaged or missing goods, are noted during this inspection phase. Once the inspection is complete, the details are recorded in the GRN, and the document is signed off by authorized personnel. Copies of the GRN are then distributed to relevant departments, such as procurement, finance, and inventory management, ensuring that everyone involved in the supply chain is informed and aligned.

- Manual data entry increases the likelihood of mistakes, such as incorrect quantities or misfiled records.

- A GRN (Goods Received Note) is basically a document which acknowledges the goods’ delivery to a consumer by the supplier.

- For more insights, consider exploring TaxBuddy’s guide on Goods Received Note.

- It helps track inventory costs, maintain financial records, and prevent discrepancies in the accounts payable process.

- A Goods Received Note (GRN) is an internal document created by a company’s receiving or warehouse team to confirm the arrival of goods from a supplier.

- Verifying deliveries before payment helps businesses avoid paying for missing, incorrect, or damaged items—ensuring payments are made only for goods that were actually delivered.

- Without a GRN, businesses could end up paying for items that were not received, leading to financial losses.

- Accounting departments will require it for recording inventory transfer from place to place.

- Automation can further enhance the GRN process, with inventory management software reducing manual errors and improving data accuracy.

- For example, if a business orders 500 office chairs, the warehouse team can use the GRN to confirm whether all 500 units were delivered according to the purchase order.

- Each GRN adds to a growing data set on vendor reliability, delivery timelines, and quality consistency.

- Fifth, failing to account for partial deliveries can disrupt the entire supply chain.

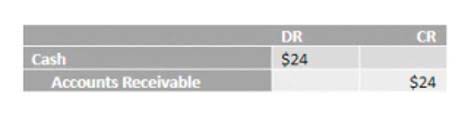

Tipalti finance automation software products provide robust GRN and PO matching and other efficient, cost-saving features for handling your business’s global procure-to-pay cycle. The Goods Received Note also establishes that the condition and specifications of the goods received are acceptable or notes otherwise for follow-up with the supplier. If the GRN indicates that the goods ordered are damaged or missing, the finance department should not pay for those items that don’t meet the PO terms. It will usually be sent along with the invoice and the actual delivery of goods as a record of goods received.